Key features of G3 Pro Foam Polishing Pad – Farécla

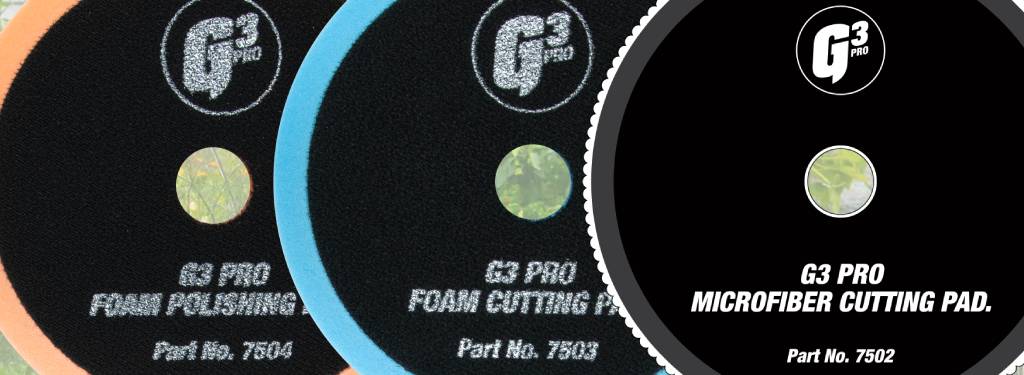

G3Professional (Farécla): I have been fortunate enough to acquire a set of their pads for appraisal. The test range consists of 3 pads.

Blue – Foam Cutting Pad 7503

White – Microfibre Cutting Pad 7502

Orange – Foam Polishing Pad 7504

What We Say:

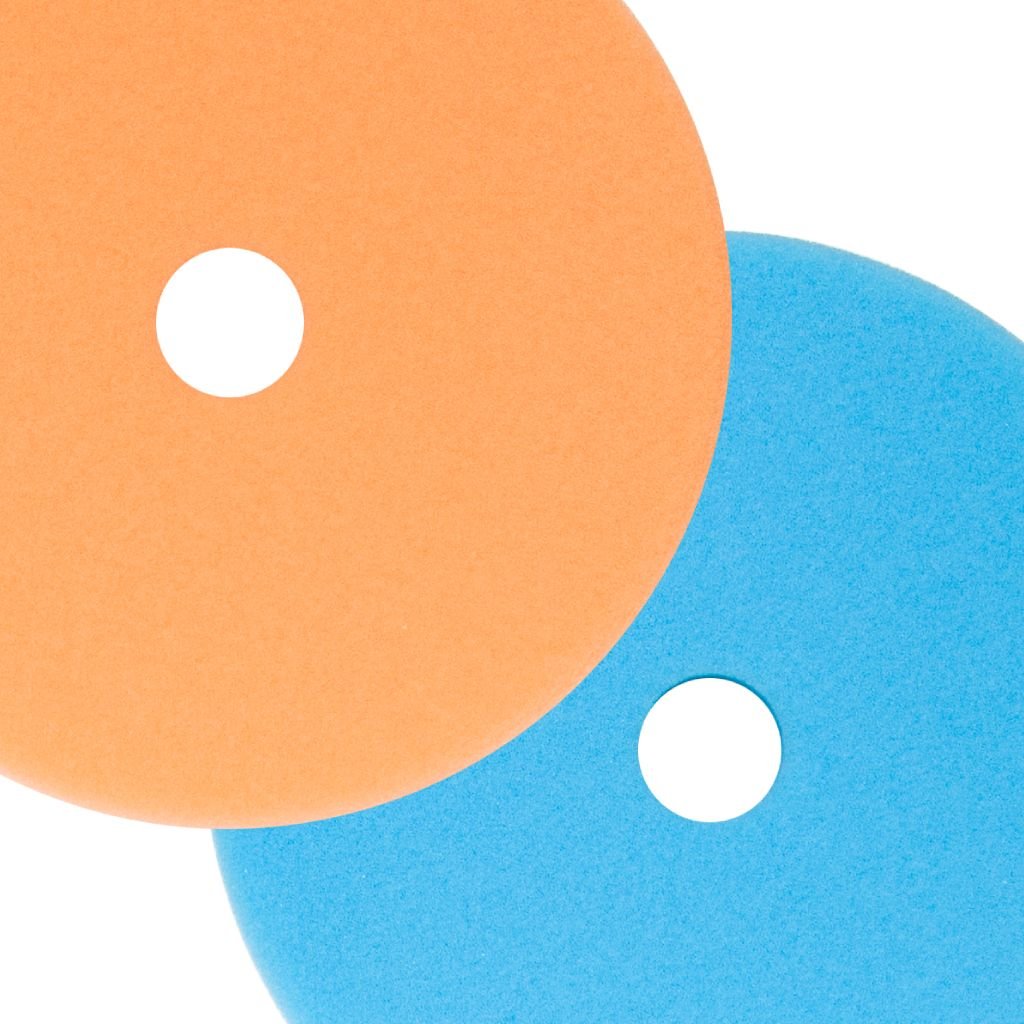

These pads have been well thought out and a few nice featured built into them. The pad in itself is 150mm / 6” across the diameter and approximately 40 mm thick for the foam & 12 mm thick for the microfibre. Much like Meguires or Rupes pads.

Straight off those who have been polishing and refining paintwork for a good while will feel at home with these pads. But the main stand out difference is with its tapered edge on the foam pads and a centre cooling hole.

These features have been added bonuses as due to the nature of polishing. When polish is applied and worked centrifugal force comes into play covering more area while all the time keeping the centre cool. Correction on the polisher is all about working the abrasive and working them well.

Most of the correction or refining is done on the outer edges of any pad, as this is where the greatest speed and forces are exerted. On a 6 inch pad the outer edge of the pad travels at approx. > 38 FPS @1500rpm. (Feet Per Second) So a continual flow of polish and lubricates across the surface of the pad to the outer edge will be beneficial.

Advantage of the hole: It also acts as a cooling zone to save hot spots within the pad. This is common with the thicker pads. This normally cause delimitation of the glue which held the Velcro to the pad, and is some instances cause the polish trapped within the inner core of the pad to boil. Damaging the internal foam structure of the pads and causing premature internal collapsing.

Moving on to a few other advantages of the pad design.

The pads all come clearly marked on the with a handy cut scale as well as the boxes.

The shape of the pad also gives greater safety.

This tapered design aid polishing deeper internal contours and the pad moulds itself into these areas without fear of the backing plate coming in contact with the paint. Even on the microfibre compounding pads which are normally unforgiving in these areas.

Also when polishing down to a protruding edge or protruding side skirts. The leading narrow edge of the pad cuts down on the size of any hot spots that may build up if the user comes in contact with the edge. I would still recommend taping up these areas as part of the course though.

Generally I was quite impressed with the G3Pro pads and where they have advantages.

1. There mould nicely to internal contours.

2. Cut down on possible micro marring due to the foam construction.

3. Keep heat build-up down on the panel as well as internally within the foam.

4. Volume of polish is considerably reduced.

5. Nice size and shape.

6. Good selection of cut without over complicating issues.

7. Easy to read scale on each pad and box.

Promote your brand & products. For shoutouts and business inquiries, direct message or email us info@waxedperfection.co.uk